The Main Principles Of Mhs - Material Handling Supply Inc.

The Main Principles Of Mhs - Material Handling Supply Inc.

Blog Article

Little Known Facts About Mhs - Material Handling Supply Inc..

Table of ContentsMhs - Material Handling Supply Inc. for BeginnersThe 4-Minute Rule for Mhs - Material Handling Supply Inc.Getting My Mhs - Material Handling Supply Inc. To WorkSome Ideas on Mhs - Material Handling Supply Inc. You Need To KnowMhs - Material Handling Supply Inc. for BeginnersThe Ultimate Guide To Mhs - Material Handling Supply Inc.

This line is called the line of action. Forklift dealer. If the bottom of this line goes beyond the security triangle since a load is also heavy or expensive, or since the forklift is not on a degree surface it will topple. A vertical line expanding from the center of gravity of the vehicle-load mix must stay inside the stability triangular to protect against the forklift from tippingThe various other concept to comprehend is the forklifts center of gravity. When unloaded, the forklifts center of gravity is right regarding right here.

Much heavier tons change the center of gravity ahead also further. Raising the tons additionally shifts the center of mass onward. In order to avoid the lift from tipping, the consolidated facility of gravity of the load and the lift should remain inside the stability triangular (at ground level) in any way times.

Mhs - Material Handling Supply Inc. Can Be Fun For Anyone

If you have a balanced load, the load is unlikely to impact the side-to-side center of mass. https://giphy.com/channel/mhsinc30677. Yet if you drive on a sloped surface, your center of mass might pass beyond the security triangular and the lift can tip. Every forklift has an identification plate that details crucial information about the truck

To ensure that the center of mass of your forklift stays inside the security triangular, do not attempt to lift anything heavier than the identification plate enables. Regardless of exactly how active you are, you need to evaluate your forklift before utilizing it. If you do discover something that might impact the safety of the car you should report it quickly.

Follow the drivers guidebooks provided by the tools supplier. These guidebooks describe the risk-free operation and maintenance of forklifts. Remember, the operator is liable for the secure procedure of the forklift. Do a pre-operation examination prior to every shift. If the forklift is used around the clock, inspect it either before each change or after each shift.

Some Known Details About Mhs - Material Handling Supply Inc.

It is finished in two parts: the walk-around assessment, and, the seated inspection. It's a good idea to have a checklist to make certain you check my blog do not miss out on any steps.

Check the problem of the tires. If the forklift is an outdoor forklift with pneumatic tires, inspect the air stress and try to find excessive wear on the tires. A tire with low air pressure might trigger the lift to tip when a tons is elevated. Can a tire failing.

7 Simple Techniques For Mhs - Material Handling Supply Inc.

Seek splits or other signs of wear. Examine all fluid levels. Examine the engine for any type of signs of wear, loose connections, or leakages. Wipe up any too much oil or various other flammable material. Try to find cracks or deformities in the forks, backrest, mast, and overhanging guard. Inspect the identification plate to make certain it is undamaged and clear.

Always start the engine while seated in the driver's positionnever while standing together with the forklift. Check all assesses and cautioning lights, and the battery or fuel degree. Lift and lower the forks, and turn the mast.

Indicators on Mhs - Material Handling Supply Inc. You Need To Know

You'll need to appear the horn at crossways, and wherever vision is obstructed. Examine the brakes by depressing the brake pedal. There ought to be some resistance. Set and examine the hand brake. Check the steering. A great deal of play or tough guiding will minimize your control. Relocate the forklift forward a couple of feet.

Leaks might suggest a hydraulic trouble, and fluids left on the floor are a sliding hazard. Also try to find triggers or flames coming out of the exhaust system. Pay attention for any type of uncommon sounds. If you find anything incorrect with the forklift during the walk-around or seated inspection, do not operate it up until it has been repaired.

The Ultimate Guide To Mhs - Material Handling Supply Inc.

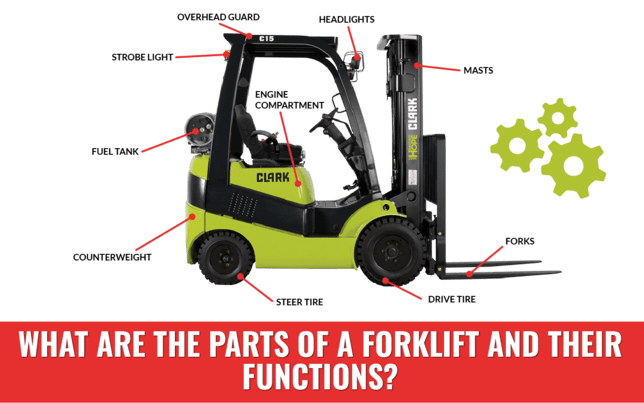

Forklifts have numerous moving components and items that permit the forklift to run appropriately. Comprehending the terminology of the parts and makeup of a forklift is vital for reliable interaction with others while at work - https://gravatar.com/tannergraves30677. Below are some of the fundamental attributes and components that compose the anatomy of a forklift truck

For a lot of forklifts, the pole is made towards the front of a forklift and directly in the forklift driver's line of vision. Forklift masts come with different sections that elevate or reduced the forklift carriage along with the forks.

Report this page